Technologies

In order to meet our high quality standards, you receive all work steps in gear cutting technology from a single source.

Technologies

Know-how meets precision

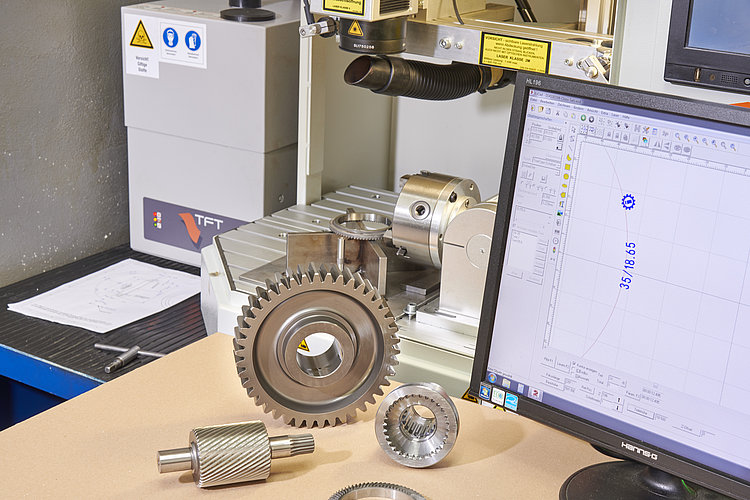

In order to guarantee our high quality standards, we at ILMBERGER carry out the majority of all work steps in gear cutting technology ourselves. Our focus is on gear milling and grinding technology.

We are constantly investing in gear cutting and testing technology in order to keep abreast of the latest developments and guarantee you the highest product quality.

Our innovative gear cutting technology at a glance:

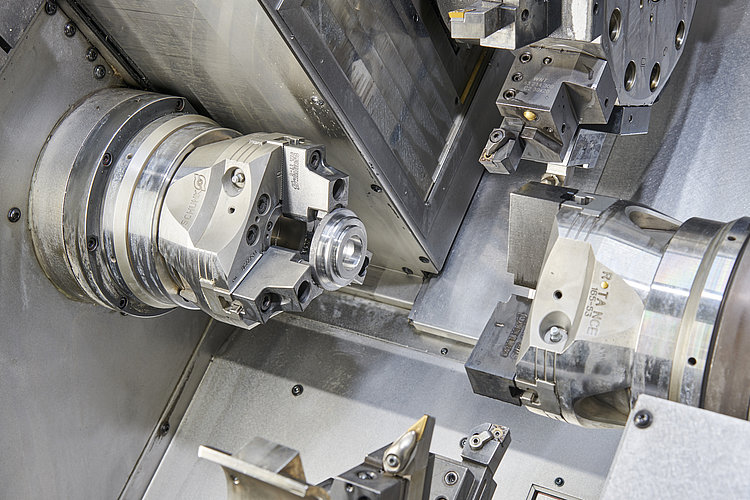

Turning

- soft

- hard

Our modern CNC lathes are capable of producing a wide variety of geometries in consistently high quality. The CNC programs are created at the 3D CAD/CAM workstation.

Milling / Drilling / Machining centers

With our 4 milling centers, we are able to carry out up to 5-axis milling in a single clamping operation. For example, hole circles are drilled in position to tooth or grooves are milled.

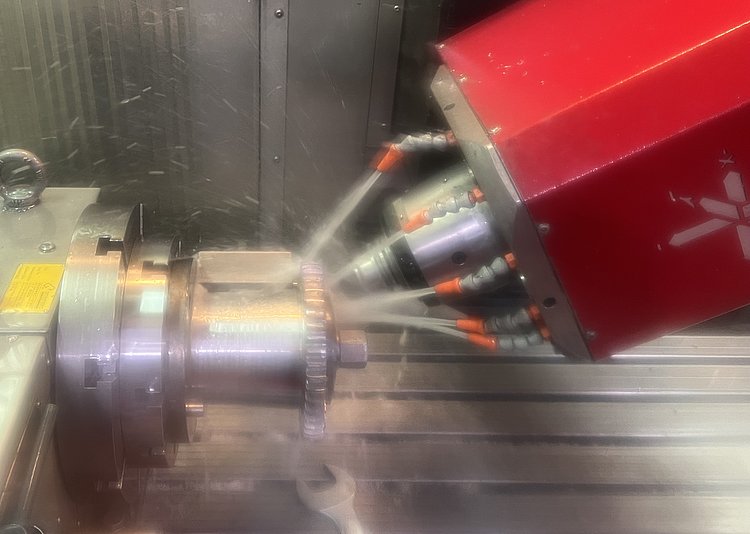

Gear Cutting

- Hobbing machines

- Bevel gear hobbing (spiral, straight)

- Gear hobbing (internal and external toothing)

- planing

- Broaching

We use different technologies depending on the quality requirements, geometric arrangement of the gearing and production quantity. We focus on gear hobbing, bevel gear hobbing (straight and spiral), gear shaping (internal and external), as well as planing and broaching (internal profiles).

Hardening

- Setting and hardening (also on a contract basis)

- Salt bath remuneration (via external partners for own production)

- Metallurgy laboratory

We can quench and temper, carburize, harden, temper and stress-relief anneal in our multi-purpose chamber furnace. We can also nitride in the bath (with the help of partner companies), salt bath hardening and mandrel hardening in the rotary hearth furnace. The parts are then tested in our own hardening laboratory and the results documented (in particular EHT or NHT, surface hardness, core strength).

Grinding

- External and cylindrical grinding

- Internal cylindrical grinding

- Surface grinding

- Tooth flank grinding

Our various CNC grinding machines allow us to meet high fit and accuracy requirements. We can perform external and internal cylindrical grinding, face and surface grinding and, of course, tooth flank grinding (profile and generating grinding).

EDM - Electrical Discharge Machining

Since the beginning of 2023, we have also been able to cut our gear parts using EDM. Wire erosion means, an electric current flows from the electrode (in wire erosion, this is the approx. 0.2 mm thick wire) to the workpiece. The spark discharge then erodes the workpiece to the desired shape. The entire process takes place in a deionized water bath. For example, a hexagonal inner profile is eroded into a bevel gear.

Trowalizing

Depending on the type of abrasive used, we can deburr, descale, grind, matt or polish the workpieces in our vibratory finishing machine.

Laser Labeling

At the end of the production process, the gearing parts are labeled according to customer requirements. In the case of bevel gears, for example, the optimum assembly dimension, the batch number or even a logo is lasered onto the component. But even a tiny multicode with lots of information is possible.